Automated Production Lines for Sheet Metal Processing

News / Oct. 14, 2025

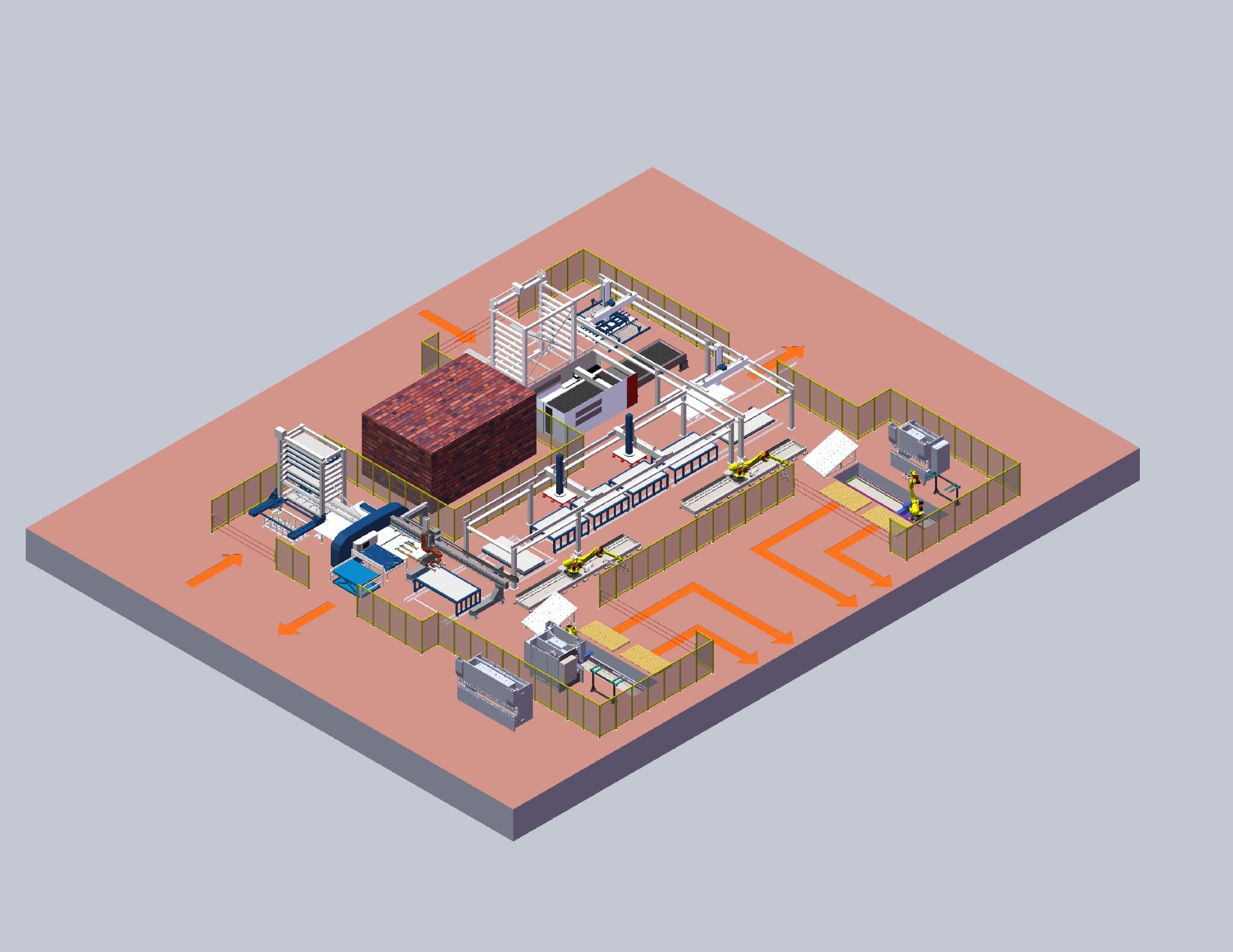

A leading manufacturer of HVAC systems sought to automate its entire sheet metal production process. To address the bottlenecks inherent in traditional manufacturing methods, the company required the development of a fully automated production line encompassing the complete workflow—from blanking and punching to transfer and bending. The objective was to reduce costs, enhance efficiency, and improve processing stability.

Our Solution

The production line mainly consists of four major units + central control software:

- Laser cutting: Supera 3015-F 6000W fiber laser cutting machine, equipped with an automated tower storage system loading/unloading devices

- Punching and forming: DINAMICA 3.1550 CNC servo turret punch press, equipped an automated tower storage system loading/unloading devices

- Sheet Transfer and Sorting system: Featuring an automatic 10 station pallet system, with full automated truss-based material handling system with fully automatic sorting, equipped with upper and lower electric carts for transfer and buffering;

- Automatic Bending Cells: Two hydraulic-electric hybrid pump-controlled bending machines and a FANUC robot, completing the final forming operations;

- Central Control Software: Decomposes and distributes production tasks, coordinates the complete productions progress, ensures stable and efficient production operations across the line.

Supera 3015-F 6000W

DINAMICA 3.1550 CNC servo turret punch press

Sheet Transfer and Sorting system

Two hydraulic-electric hybrid pump-controlled bending machines and a FANUC robot

Topics:

Are you interested in our products?

A sales executive will contact you within 24 to 48 hours.